Stalling : to delay taking action in order to have more time. Erroneous concept in my view as we can never win or lose time, just have the impression of it. Instead of installing the engine which should have been delivered 7 months ago and following the normal build sequence, I philosophize and stall !

The lack of spare parts and components affecting almost all areas those days is the cause of the delay but isn’t that annoying after all. We still have a lot of work that can be done without an engine hanging. The beautiful MT 3 blade propeller will wait some more to find its place.

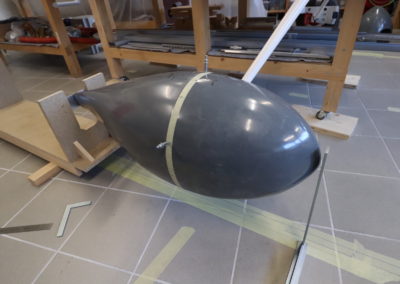

Skipping cowl and propeller chapters I start with the wheels, quite straightforward and quick but highly symbolic ! Gear leg and wheel fairing is a lot more complex. Clever geometrical exercises are necessary to ensure they are installed in the flight axis and not in the wheel axis as the wheels are pinched and inclined to help steering straight on the runway.

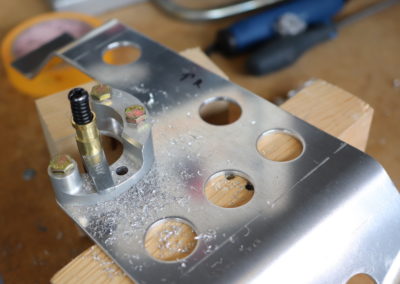

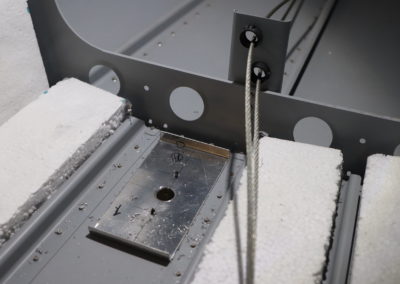

Electrics and avionics are dealt a little to no in the builder documentation as there are so many options possible. After some major brainstorming I start to mount my 9 antennas (communication, navigation, GPS…) trying to respect minimal distances and other technical requirement.

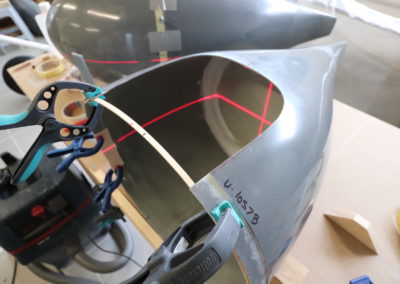

I also start to work on the static system (airspeed and altitude information) and incorporate 2 service bulletins for the replacement of a rudder hinge and the installation of an improved flaps motor. Strange feeling to already modify an aircraft that has not yet flown ! I meet again my empennage, stored in the past 4 years, dedust and reassemble it with great joy to add some fiberglass tip fairings.

Step by step, we progress !