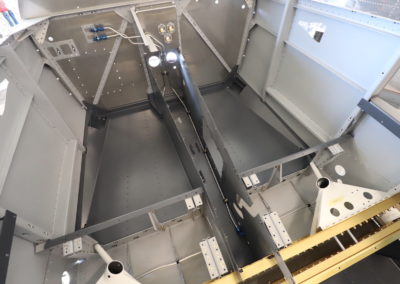

October 2021, I start the two components interior paint, a lot more resistant than the grey primer used on less solicited parts. I have to mask everything not to be painted inside the fuselage and built a booth around to avoid painting the workshop and everything inside it in black! It’s a lot of work for little treated surfaces but the result is perfect for the automotive painter apprentice I am.

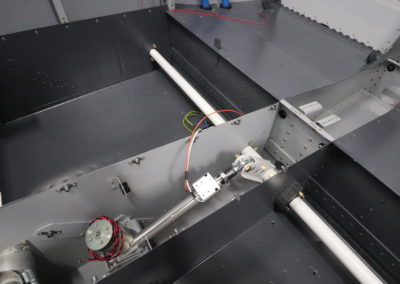

System installation on the other hand doesn’t go at all as planned. I realize page after page that I am missing strategic parts or tools. This is slowing me down, I start no less than 4 chapters (brakes lines, fuel lines, flight controls and flaps controls) without being able to finish any. It’s frustrating but one gets used to it. Waiting for those essential parts, I decide to start working on the fiberglass cabin top, a big chunk both literally and figuratively! I work outside and take advantage of the last beautiful days before winter. I have to cut and sand this unnecessarily oversized part, to assemble it and remove it from the aluminum fuselage thanks to some pulleys and restart the all process until it’s perfectly adjusted. Working with fiberglass is very different than aluminum, it’s a new experience, messy but interesting. The long-awaited moment comes when the top is finally and permanently secured in place. The curves allowed by the fiberglass are gorgeous…

The fuselage finally looks like… A fuselage!

End of November the 4th kit crate is delivered. The finish kit includes among other things, the doors, the seats, the engine support and its cowling, gear legs and fairings and several pounds of hardware, amply enough to get busy for a year…

After having unpacked all that with always so much fun and admiration for the way it is organized, without having really completed system installation, I start working on the butterfly doors. Only for them, two good months of work and kilos of dust will be necessary to have the pleasure of seeing them assembled, closed or their wings deployed… Each door is made up of 2 shells, inner and outer that must be cut, adjusted and glued together. Then comes final adjustment in their housing: assembly, disassembly, sanding… Ad infinitum. The hinge and closing mechanism are well thought out but rather complex.

In February 2022 the fuselage kit is considered completed…. It is not really the case but it sounds so good !